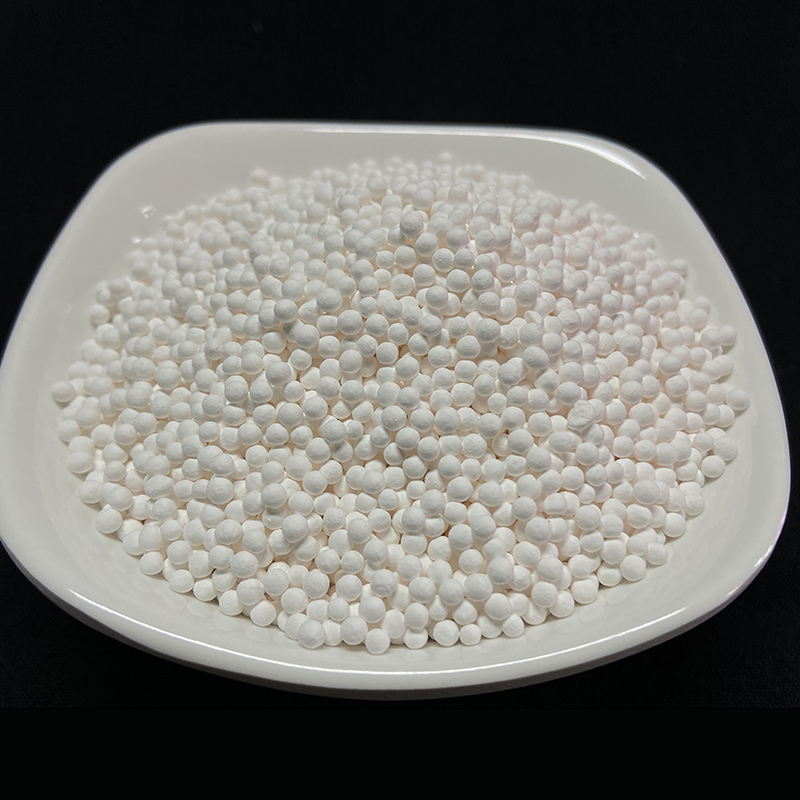

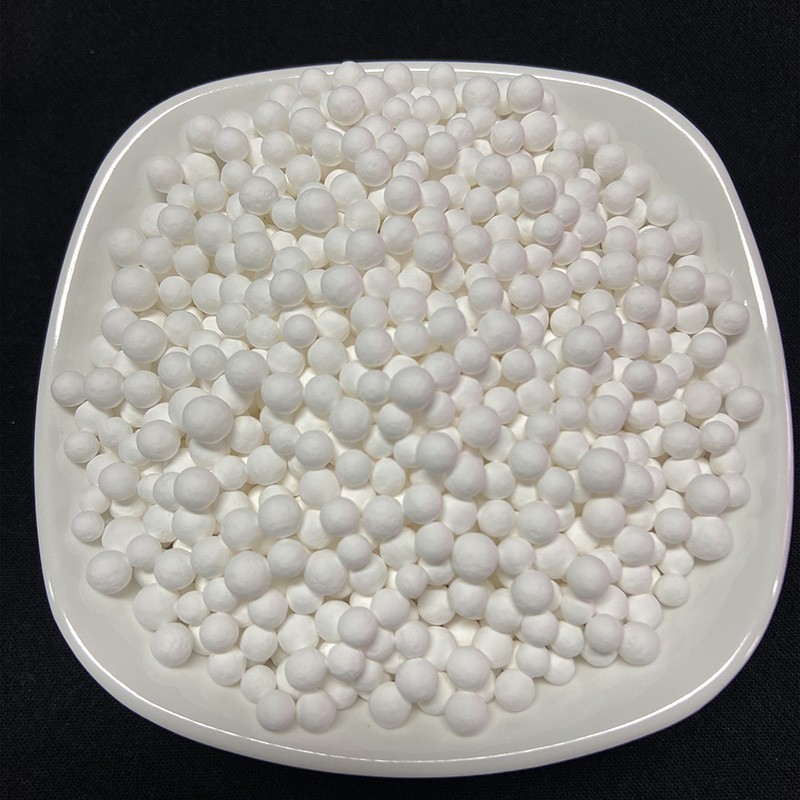

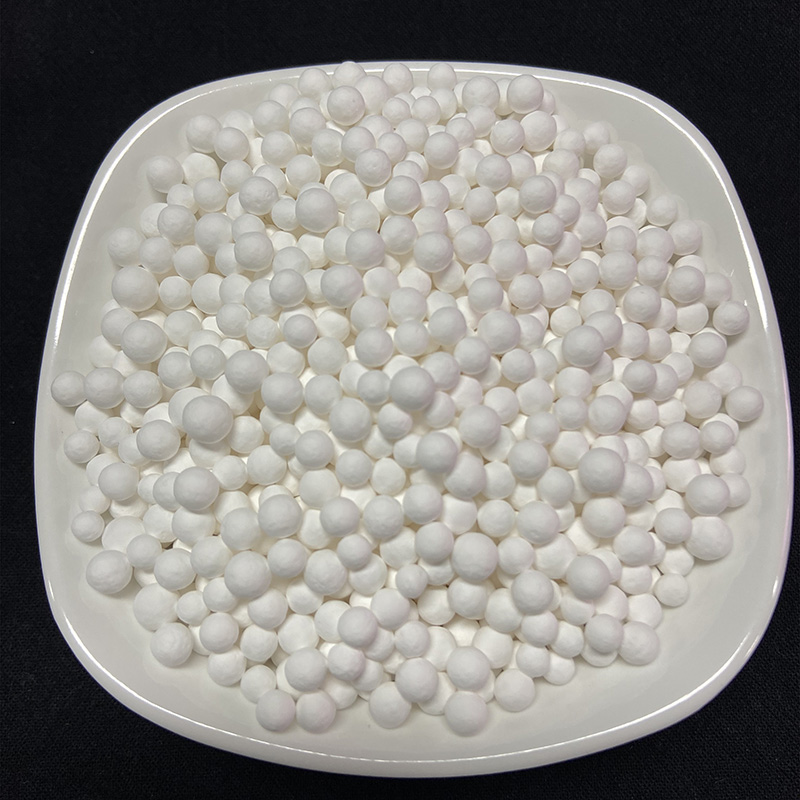

Alumina Keramik Filler Dhuwur Alumina Inert Ball / 99% bal Keramik alumina

Sifat Fisik lan Kimia Bola Keramik Inert

| Sifat fisik lan kimia saka bal keramik inert | |||||||

| unsur | Al2O3% | 60 | 70 | 80 | 90 | 95 | 99 |

| Fe2O3% | ≤0.9 | ≤0.8 | ≤0.6 | ≤0.4 | ≤0.3 | ≤0.1 | |

| Komponen isih bisa ditemtokake liwat rembugan antarane supplier lan panuku yen perlu. | |||||||

| panyerepan banyu,% | 3±1,Iki uga bisa ditemtokake kanthi rembugan antarane supplier lan panuku | ||||||

| proporsi, kg/m³ | 2.5-3.0 | 2.7-3.2 | 2.9-3.2 | ≥3.1 | ≥3.2 | ≥3.4 | |

| Kapadhetan akeh, kg / m³ | 1400-1550 | 1400-1650 | 1500-1800 | 1700-1950 | 1800-1950 | ≥1900 | |

| Lebu, retak utawa pecah | Tas siji kurang saka 5% | ||||||

| Penyimpangan ukuran | Bal seragam, rasio diameter paling gedhe nganti paling cilik saka bal keramik ora ngluwihi 1,2 | ||||||

| Toleransi dimensi | ≤10mm | ± 1.0 | |||||

| 11-25 mm | ± 1.5 | ||||||

| 26-50 mm | ± 2.0 | ||||||

| ≥50mm | ± 3.0 | ||||||

| Kekuwatan tiba gratis | Tingkat rugi ≥99% | ||||||

| Kekuwatan kompresif | φ3 | ≥250 | ≥300 | ≥350 | ≥400 | ≥500 | ≥500 |

| φ6 | ≥800 | ≥1000 | ≥1000 | ≥1200 | ≥1500 | ≥1500 | |

| φ8 | ≥1500 | ≥1600 | ≥1800 | ≥2000 | ≥2500 | ≥2500 | |

| φ10 | ≥2000 | ≥2500 | ≥2800 | ≥3000 | ≥3500 | ≥3500 | |

| φ13 | ≥3000 | ≥3000 | ≥3500 | ≥4000 | ≥5000 | ≥5000 | |

| φ16 | ≥3500 | ≥4000 | ≥4500 | ≥5000 | ≥6000 | ≥7000 | |

| φ20 | ≥6000 | ≥6000 | ≥7000 | ≥8000 | ≥10000 | ≥12000 | |

| φ25 | ≥7000 | ≥7000 | ≥8000 | ≥10000 | ≥15000 | ≥17000 | |

| φ30 | ≥8000 | ≥9000 | ≥10000 | ≥12000 | ≥17000 | ≥19000 | |

| φ38 | ≥10000 | ≥12000 | ≥13000 | ≥15000 | ≥20000 | ≥22000 | |

| φ50 | ≥12000 | ≥14000 | ≥16000 | ≥18000 | ≥22000 | ≥26000 | |

| φ75 | ≥16000 | ≥18000 | ≥20000 | ≥22000 | ≥25000 | ≥30000 | |

| 50-75 | 55-75 | 60-80 | ≥80 | ≥82 | ≥85 | ||

| Wear rate% | ≤2 | ≤1 | |||||

| kelarutan asam % | ≤6 | ||||||

| alkalinitas % | ≥77 | ≥85 | ≥90 | ≥92 | ≥95 | ≥97 | |

| Refractoriness, ℃ | ≥400 | ≥500 | ≥700 | ≥1000 | ≥1000 | ≥1000 | |

| Tahan kanggo prabédan tekanan dadakan | Tingkat non-destruktif ≥ 99%, ora ana owah-owahan ing kekuatan tekan lan tekanan sawise owah-owahan dadakan kurang saka 25% | ||||||

| Tahan kanggo owah-owahan suhu dadakan | Tingkat rugi≥99% | ||||||

| Paket | Kemasan drum besi | Dikempalken ing drum wesi, disegel nganggo tas plastik PP utawa PE sing kandel | |||||

| Kemasan tas anyaman | Kasedhiya ing tas anyaman sing kuat lan tahan UV | ||||||

| Cathetan: Data kapadhetan akeh mung kanggo referensi, ora minangka basis kanggo ditampa. | |||||||

Cathetan liyane: Waca Tabel 5 Kanggo Penyerapan Banyu saka 99 Ball Pengisi

| 99 Isi Ball banyu panyerepan | ||

| 99 pangisi | diameteripun | diameteripun |

| muter mbentuk | φ<25 mm | <5% |

| Mesin press mbentuk | φ> 25 mm | <10 |

99,5% Indikator Teknis

| Al2O3 | ≥99% |

| SiO2 | ≤0,14% |

| Fe2O3 | ≤0,04% |

| CaO + MgO | ≤0,03% |

| TiO2 | ≤0,06% |

| Na2O | ≤0,1% |

| K2O | ≤0,1% |

Indeks Fisik Bola Pengisi Kimia

| KONDISI | INDEKS |

| loading softening (yb/t370-1995) | Deformasi ing tekanan 0.2mpa kurang saka 0.6% |

| Ketahanan kejut termal (yb/t376.2-1995) | 1200 ° C nganti 600 ° C. 10 kaping tanpa retak permukaan |

| Owah-owahan baris maneh (gb/t3997.1-1998) | 1400 ℃ kanggo 12 jam, Nilai maksimum 0,25%, Nilai rata-rata kurang saka 0,20% |

| Kapadhetan akeh (gb/t2997-2000) | 3,2-3,50 g / cm3 |

| kekuatan remuk | Ketemu luwih saka 230 kg/cm2 |

| Porositas sing katon | 12-18% |

| Kapadhetan akeh | 2.1-2.3g/cm3 |

Pengemasan Bola Kimia

1) Kemasan biasa: tas anyaman polietilen kanthi bobot net 25kg, ditambah pallet

2) Kemasan drum baja: kemasan drum baja 100L, palet bisa ditambah